This complete liquor packaging production line is intended to produce liquor products efficiently; the entire line has a capacity of 24000 BPH per hour. The system includes bottle depalletizing, bottle pallet/tray picking and placement, case packing lines, palletizer lines, and more, with ISO 19001 management and CE machinery certificate.

Core modules include:

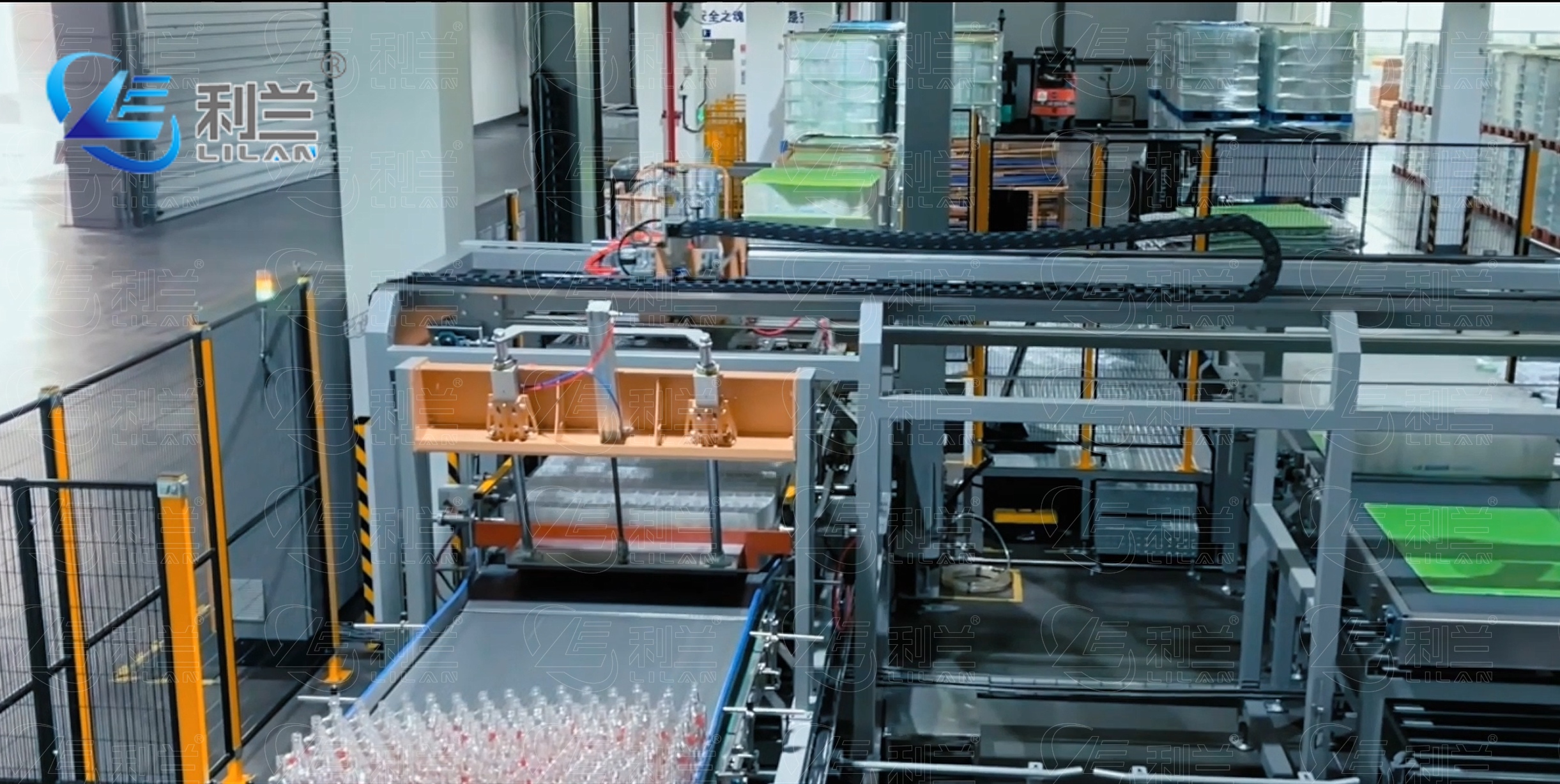

Gantry Depalletizing:

This depalletizer is used to unload the empty bottles/cans from the full stack automatically, which can improve the site working condition and production efficiency to satisfy customer’s production and packaging requirements.

Case Packing System(Servo Divider for glass bottles):

The carton packing machine can pack product into cartons according to a certain arrangement with cardboard and tray picking and placing Mechanism. This carton packing machine is fully automatic robotic carton packing machine, robot control the pneumatic gripping head of bottle to complete the horizontal movement and lifting movement to realize the carton packing actions.

Robot Palletizing:

The Robot palletizer is designed for the characteristics and applications of wine water and beverage industry, carton, plastic box, film pack palletizer, with fast speed, high production efficiency, low failure rate, simple operation and other characteristics.

Let me know if you’d like to emphasize specific subsystems (e.g., labeling, leak detection) for further refinement.

Shanghai Lilan Company specializes in intelligent packaging solutions for more than 50 global food and beverage companies. Its patented technologies include robotics control, visual inspection, and industrial platforms.

Post time: May-28-2025