OEM Manufacturer Robot Palletizer for Bag cartons Palletizing Machine of Twin Pallets

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for OEM Manufacturer Robot Palletizer for Bag cartons Palletizing Machine of Twin Pallets, If possible, make sure you send your necessities with a detailed list including the style/item and quantity you require. We’ll then mail our greatest selling prices to you.

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for , Our company insists on the purpose of “takes service priority for standard, quality guarantee for the brand, do business in good faith, to deliver qualified, rapid, accurate and timely service for you”. We welcome old and new customers to negotiate with us. We’ll serve you with all sincerity!

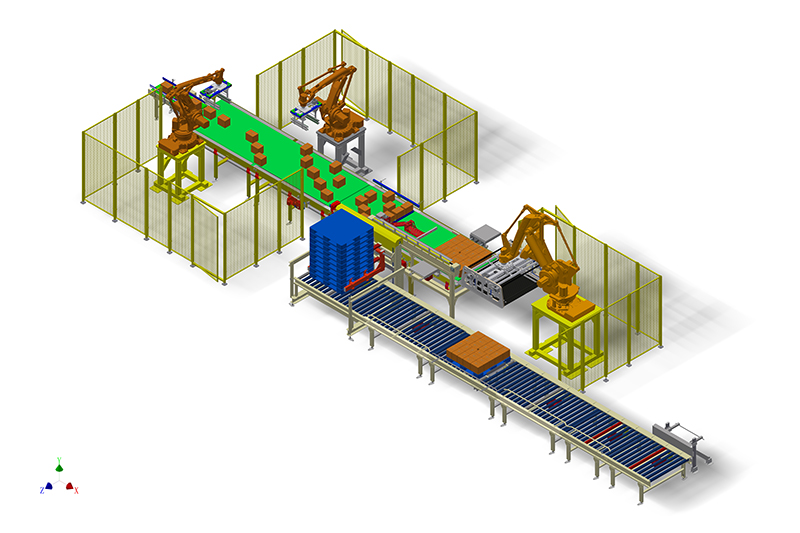

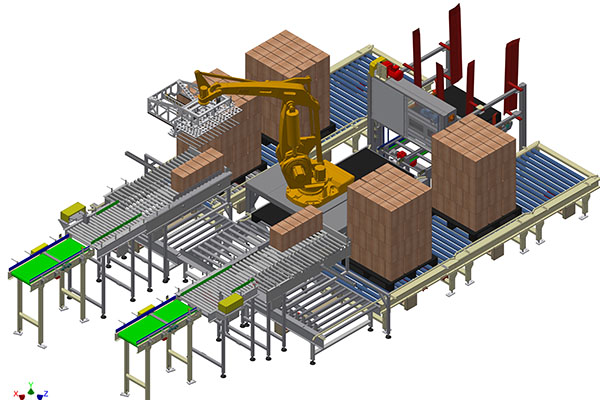

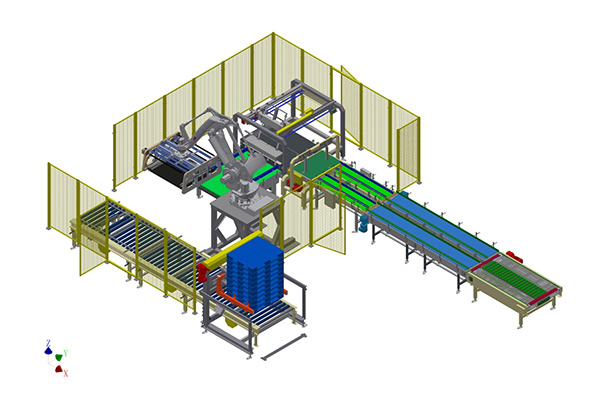

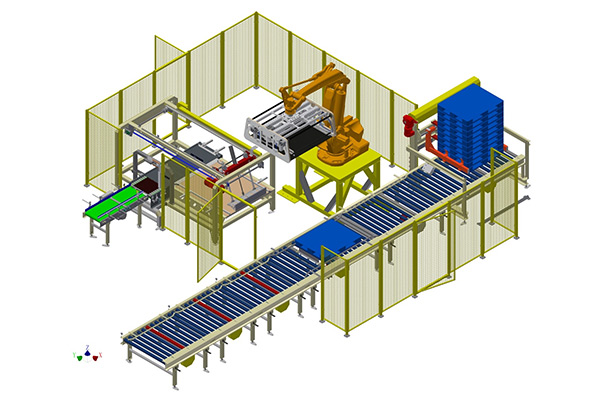

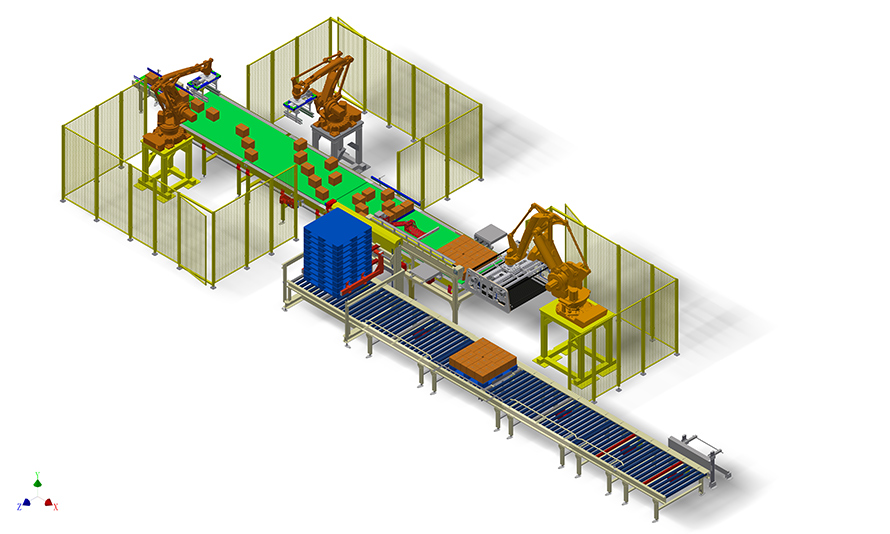

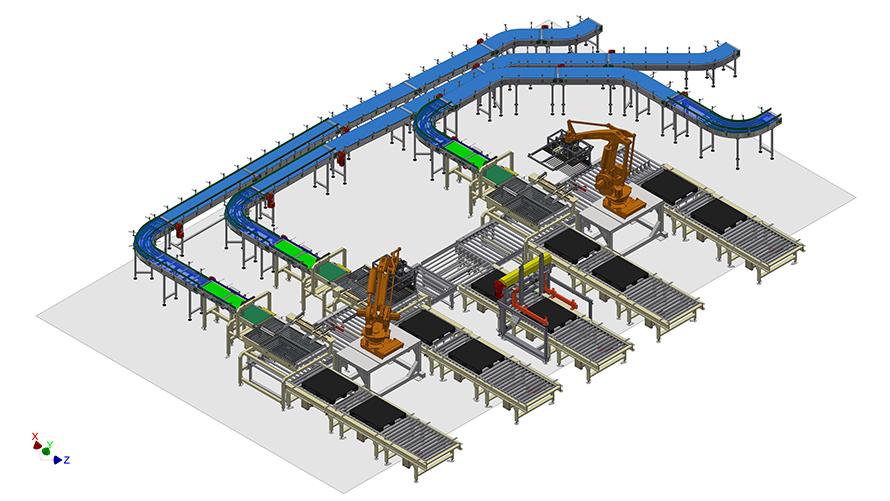

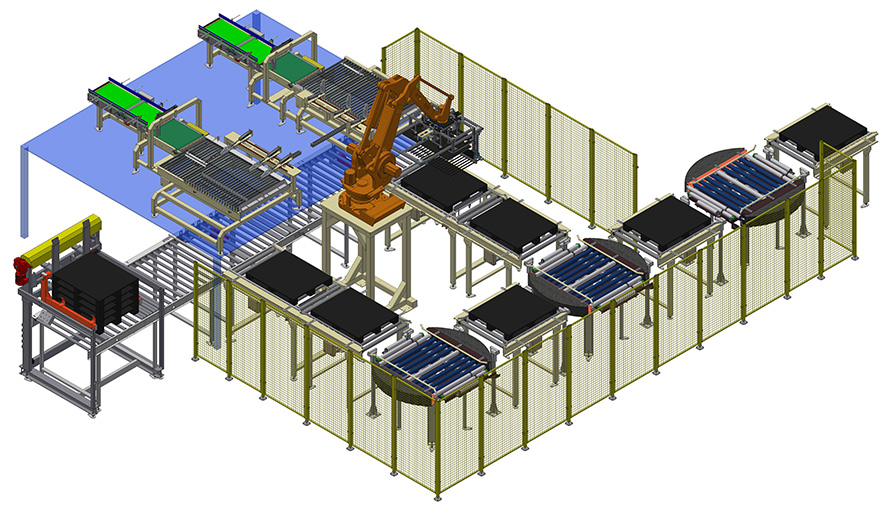

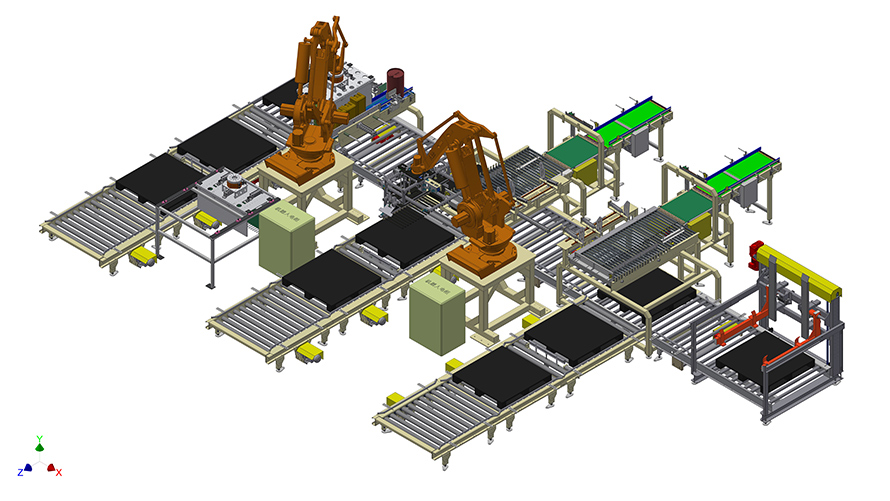

Types of Palletizing & De-Palletizing

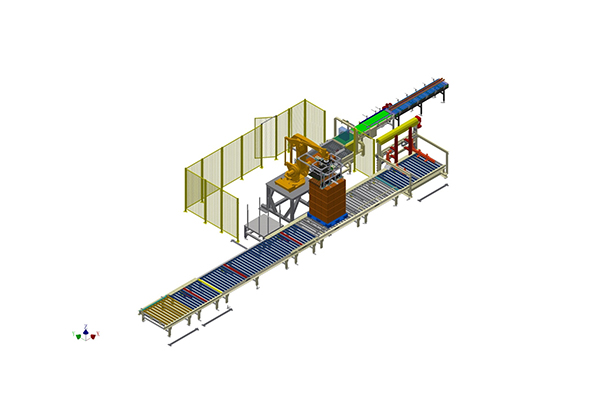

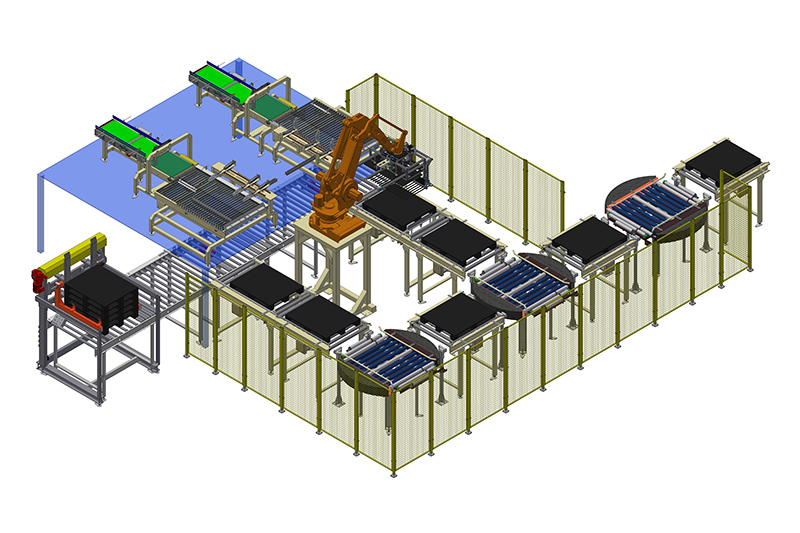

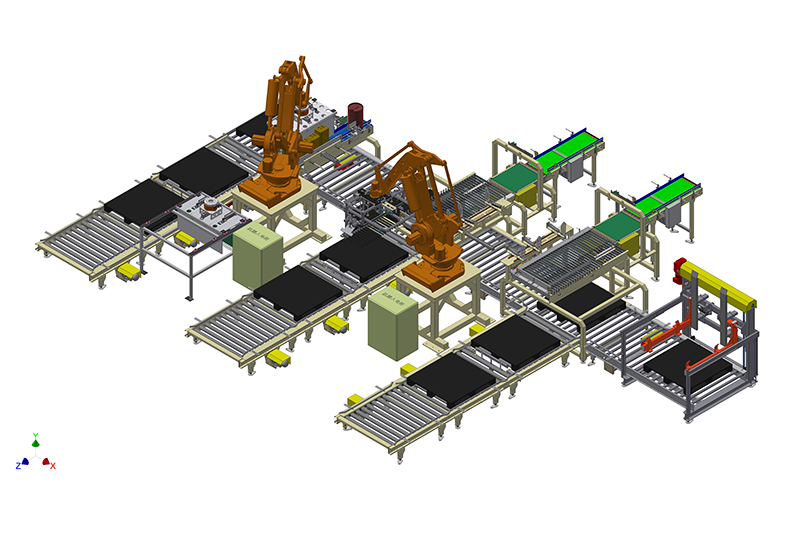

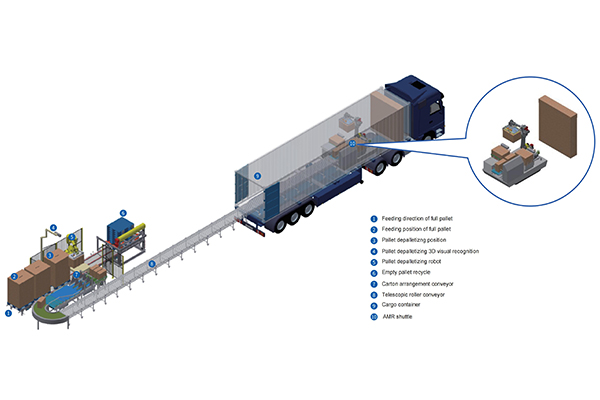

Robot Palletizing Systems

We design standard and customized palletizing systems that can increase productivity and save you money. Modular design offers flexibility, high output, and simple operation. Our robot palletizing systems are flexible and can handle virtually any product, including heavy cases, bags, newspapers, cartons, bundles, pallets, pails, totes or trayed products.

|

SPECIFICATIONS FOR AUTOMATIC ROBOT PALLETIZER |

|||

| Robot arm | Japanese brand robot | Fanuc | Kawasaki |

| German brand robot | KUKA | ||

| Switzerland brand robot | ABB | ||

|

Main performance parameters |

Speed capacity | 4-8s per cycle | Adjust according to products and arrangement per layer |

| Weight | About 4000-8000kg | Depend on different design | |

| Applicable product | Cartons, cases, bags, pouch bags, crates | Containers, bottles, cans, buckets, bags etc | |

| Power and air requirements | Compressed air | 7bar | |

| Electric power | 17-25 Kw | ||

| Voltage | 380v | 3 phases | |

Main configuration

|

Item |

Brand and supplier |

|

PLC |

Siemens(Germany) |

|

Frequency converter |

Danfoss (Demark) |

|

Photoelectric sensor |

SICK (Germany) |

|

Servo motor |

INOVANCE/Panasonic |

|

Servo driver |

INOVANCE/Panasonic |

|

Pneumatic components |

FESTO (Germany) |

|

Low-voltage apparatus |

Schneider(FRANCE) |

|

Touch screen |

Siemens (Germany) |

Main Features

- 1) Simple structure, easy in installation and maintains.

- 2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

- 3) When there is some change about the production line, just need to modify the software program.

- 4) Running in a high automatization and intellectualization,no pollution

- 5) Robert Palletizer takes less space and more flexiable , accurate compared to the traditional palletizer.

- 6) Reducing a lot of labour and labour cost, more productive.

More video shows

- Robot palletizer for cartons

- High speed robot formation palletizer for cartons

- 24000BPH deep sea water bottle production line in France shrink film packing and robot palletizer

- Modular design robot palletizer saving facotry space

- robot palletizer for two carton packing lines

- Robotic palletizer with two infeed lines

- Robotic palletizer for rice/cement/animal feeds bag

All our palletizing solutions dialogue with robotic wrapping and labeling systems and automated laser-guided vehicles, ensuring fully automated and integrated end-of-line management. They are directly connected to production lines and operate at speed with maximum reliability. Palletizers automatically stack finished products, in cardboard boxes or trays, onto pallets, managing diverse product types quickly, flexibly, and with extreme delicacy. The robot handling pickers are indeed designed to reduce pressure on the finished goods, thus preserving their integrity.